|

Author

|

Topic: Graduated nut rollers, swapping between brands?

|

David Doggett

Member From: Philadelphia, Pennsylvania, USA

|

posted 07 March 2003 12:25 PM

profile

posted 07 March 2003 12:25 PM

profile

[Note added: see the second page of this thread for listings of roller measurements for various manufacturers for the purpose of mixing and matching. Please add the measurements of the rollers on your own guitar(s) if they are not already listed.]I recently acquired a Fessenden S12U. It is a great guitar, but unfortunately does not have graduated rollers at the nut, so the strings are not flat across, especially the lowest two. This causes string rattle when playing the first few frets and also increases bar noise on the unplayed lower strings. This would seem to be a problem on a 10-string, but is especially bad on a 12-string with the really large diameter lower strings. I know that the new MSAs have graduated rollers, and my Emmons P/P 12-string has rollers with larger grooves for the lower strings, although they do not appear to be graduated. Does anyone know if I could simply use another manufacturer's graduated rollers (and axle?) on my Fessy? This would be a simple and inexpensive remedy. I'm hoping some manufacturer or experienced repair person will have first hand knowledge about this. Otherwise, if someone who has graduated rollers would carefully measure the axle diameter and length, and roller widths, I could compare that to my Fessy head piece to see if they would fit. Even 10-string measurements would be helpful, presumably if they are compatible I could just get the 12-string set from the same manufacturer. Thanks loads for any comments. ------------------

Student of the Steel, and cheap instrument connoisseur: customized 1970 Sho-Bud Maverick, Fessy S12U, Emmons S12 E9 P/P, Nashville 400, Fender Squire, Peavey Transtube Supreme into JBL 15", 1968 Gibson J50, '60s Kay arch-top, 7-string Raybro, customized Korean Regal square-neck, roundneck Dobro 90C, 1938 Conn Chu Berry tenor sax, '50s Berg mouthpiece, Hamilton upright piano. You make it, I'll play it (more or less)

[This message was edited by David Doggett on 07 March 2003 at 12:28 PM.] [This message was edited by David Doggett on 07 March 2003 at 12:46 PM.] [This message was edited by David Doggett on 11 March 2003 at 07:40 AM.]

|

Leon Roberts

Member From: Tallahassee,FL USA

|

posted 07 March 2003 01:55 PM

profile

posted 07 March 2003 01:55 PM

profile

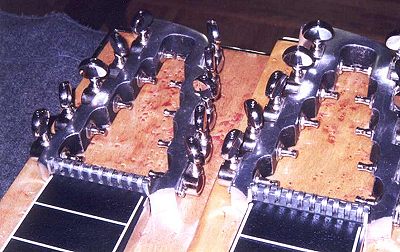

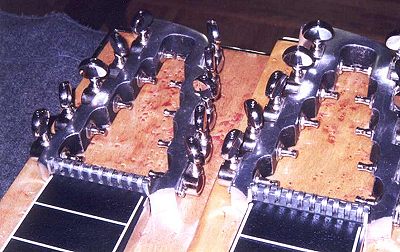

David, I replaced the nut rollers on my old Pro-III Sho-Bud with "Emmons' Nut rollers. I very carefully hand filed each slot and fitted the rollers with the tuning heads off the guitar in a vise. Now I don't mind going down to the 1st fret. I'll post a picture below. Leon

|

David Doggett

Member From: Philadelphia, Pennsylvania, USA

|

posted 07 March 2003 05:08 PM

profile

posted 07 March 2003 05:08 PM

profile

Well that's a beutiful Sho-Bud, Leon. Did it matter which axle you used? |

Larry Bell

Member From: Englewood, Florida

|

posted 07 March 2003 06:05 PM

profile

posted 07 March 2003 06:05 PM

profile

Dave,

If you can find a set for C6 you can use the bottom 5 or 6 to get the wound strings like you want them. The unwound ones don't vary much -- especially from the 5th to the 1st (range is about 013 to 017) so you can probably get by with the ones you have. I had a machinist buddy make some for my first Fessy and I'll have to do the same for my new one. It can be a long, tedious, time-consuming project to do it by trial and error -- believe me -- I KNOW. I've mentioned it to Jerry, but he hasn't taken the hint yet. It's more of a problem on a 12 string -- but what ISN'T?????

Occasionally someone will offer gauged rollers for sale on the Forum, but they don't seem to stay in business long. I'd just like to know the formula for cutting them to avoid the tedium of trial and error. You have to loosen all the strings every time you try a new combination. THAT GETS OLD FAST. If you do find a brand or other sourdce that works for the Fessy, please let me know. ------------------

Larry Bell - email: larry@larrybell.org - gigs - Home Page

2003 Fessenden S/D-12 8x8, 2000 Fessenden S-12 8x8, 1969 Emmons S-12 6x6, 1971 Dobro, Standel and Peavey Amps |

Doug Earnest

Member From: Branson, MO USA

|

posted 07 March 2003 07:00 PM

profile

posted 07 March 2003 07:00 PM

profile

String rattle is my biggest pet peeve. The problem with making the darn things right is that, at least on some guitars, the rollers are cut in a "V" shape, so that the strings don't sit in the bottom of the groove. Otherwise it would be simple to figure the difference in the size of the strings and cut accordingly. Seems that Jim Smith posted one time that all it took to figure this was "a simple trigonometric formula". (There's an oxymoron!) I believe someone with a jeweler's lathe, some know-how and the dimensions of the various slots of the popular guitars could do a good business making rollers. I'll take two sets for Zum U12's and one for a Sierra U12. My 'Bud doesn't suffer too much. Anybody out there???------------------

Doug Earnest

The only Zum Keyless U12, Fender Cyber Twin |

Larry Bell

Member From: Englewood, Florida

|

posted 07 March 2003 07:48 PM

profile

posted 07 March 2003 07:48 PM

profile

Doug, and all

Pete Burak posted on another thread that Sierra makes gauged rollers for their guitars. I don't know the axle size or roller dimensions, but it's worth a shot. And it takes care of one of Doug's guitars, but the question is whether the Sierra rollers will fit other guitars. I'd still just like to know how to calculate the size of the V for a given string gauge to make the top of the strings flat.I agree with you guys that all pedal steels -- especially a U-12 -- should be sold with the option of gauged rollers. ------------------

Larry Bell - email: larry@larrybell.org - gigs - Home Page

2003 Fessenden S/D-12 8x8, 2000 Fessenden S-12 8x8, 1969 Emmons S-12 6x6, 1971 Dobro, Standel and Peavey Amps |

Don McClellan

Member From: Kihei, Maui, Hawaii

|

posted 07 March 2003 08:53 PM

profile

posted 07 March 2003 08:53 PM

profile

I think we've all seen electric guitars with 6 individually adjustable little bridges. It seems to me someone could make individually adjustable roller nuts for pedal steels. Each on its own seperate axle that can be moved up or down with the turning of a small set screw. Why not? This way you could adjust the roller nut height for whatever tuning you're using.

I've heard that keyless steels don't really need roller nuts because the strings don't move enough to warrant them. If that's true, non-rolling, adjustable nuts would be very easy to design for keyless steels. Either way it seems like a better idea then making custom roller nuts that only fit one size string. Am I overlooking something? Otherwise, I too would like to buy some properly sized roller nuts. This is good thread and an important subject. Don[This message was edited by Don McClellan on 07 March 2003 at 08:57 PM.] |

Leon Roberts

Member From: Tallahassee,FL USA

|

posted 07 March 2003 10:27 PM

profile

posted 07 March 2003 10:27 PM

profile

Thanks David, Both the Sho-Bud and the Emmons rollers use a 1/8th shaft. At least they did in my case. My good buddy, who happens to be an Emmons parts dealer, got the rollers for me. The E-9th rollers were different from the C-6th rollers. I was very careful not to mix the rollers from neck to neck and also string position. Altering an old Sho-Bud is one thing, Changing a new Fessie is a horse of a different color. Good luck on whatever path you take.

Leon |

Jim Smith

Member From: Plano, TX, USA

|

posted 07 March 2003 11:31 PM

profile

posted 07 March 2003 11:31 PM

profile

quote:

Seems that Jim Smith posted one time that all it took to figure this was "a simple trigonometric formula".

It is a pretty simple formula, but I didn't do that well in trig class.  I drew a big V and a circle representing a string touching the insides of the V. I went through all the calculations of the side of the V being a tangent making a right angle with the center of the string, thus the hypotenuse of the triangle is the distance from the bottom of the V to the center of the circle, etc., etc., etc. Bottom line is, you don't need no stinkin' trigonometry! As long as the angle of the V stays the same, you just cut the V deeper exactly the amount you want the string to lower. Draw the diagram yourself to see, cutting the V deeper will drop the string the same amount. It turns out that adjusting the string height is much easier with V slots than with rounded slots! Phew!   Disclaimer: I'm tired from the Dallas show, and will try to think this through again when I'm more alert, but logically it makes sense to me. Look at the V on the paper again, cutting the slot deeper is exactly the same as just moving the V down the page. The relationship between the string and the V slot doesn't change a bit![This message was edited by Jim Smith on 07 March 2003 at 11:32 PM.] |

Peter

Member From: Cape Town, South Africa

|

posted 08 March 2003 04:15 AM

profile

posted 08 March 2003 04:15 AM

profile

I had the same U12 bottom strings problem. The guys on the forum suggested I put a roller on a bolt and nut and stick it in a power drill. Then use a small file (I used a round one) and hold it against the groove while running the powerdrill. I used a straight edge to visually estimate the amount to take off. I did 4 rollers this way and it worked out 99.6% correct. The other 0.4% is taken care of by the weight of the bar.

It was relatively easy in the end. It was just difficult to get started.  ------------------

Peter den Hartogh-Fender Artist S10-Remington U12-Hilton Volume Pedal-Gibson BR4 lapsteel-Guya "Stringmaster" Copy-MusicMan112RP-Peavy Rage158- - My Animation College in South Africa |

David Reeves

Member From: Florida

|

posted 08 March 2003 06:00 AM

profile

posted 08 March 2003 06:00 AM

profile

One idea you try, Usually a trade school will do machining projects to give the students some practical hands on training. If you can take a roller and a set of strings with you, they can get the dimensions of the roller, mic the strings (micrometer) and make you a set of rollers cut with rounded grooves to fit each string, usually charge no labor, the instructors will help with drawing and you pay only for the metal!

I had the the changers polished on this old sho-bud I bought at our vo-tech school and it sure made a difference in string breakage. all at no cost.------------------

"Stump" Reeves

|

Jim Smith

Member From: Plano, TX, USA

|

posted 08 March 2003 06:39 AM

profile

posted 08 March 2003 06:39 AM

profile

Regarding my previous post, I had another thought as I was falling asleep. If you have a set of calipers that will fit into the grooves of the rollers (it doesn't matter how far into the grooves, but they must fit into the grooves at least a little), the amount to file/cut will be twice the amount that the string is too high. If you only have a ruler/scale that fits into the groove, then the amount to file will be the same as the amount you want to lower the string.For example, for a string is .020" too high, and the calipers in the groove measure .360", you will cut until the groove measures .320". This is because you're measuring the diameter (twice the radius) of the groove, but the amount you want to lower the string is based on the radius. Caution: If someone really tries this, file a little at a time on one string to be sure my theory is really correct. Then if it is, you can just file the rest until they measure what you want and stick them on your guitar.  |

Larry Bell

Member From: Englewood, Florida

|

posted 08 March 2003 06:46 AM

profile

posted 08 March 2003 06:46 AM

profile

Jim,

Do you use the same size V for all strings?My machinist buddy made the tools ('Vs') that he used for cutting mine and insisted that he needed several sizes for it to work properly. The ones on the black guitar are pretty good, but I have the same problem with the new one and need to cut to the chase a bit quicker. It would sure be nice if someone just made them to specs for sale, but I still have problems telling them what those specs are. So, if you have a range of, say, 074 to 011, do you use the same tool on the lathe for all of them? Tell JF the guitar is great and I sent him an EMail if he gets a chance to check it. Enjoy the show! Wish I were there. ------

Just noticed your response --

I'll take this stuff to the machinist and see if it makes sense to him. I'm a real mechanical nimrod, but happen to manage a group with a couple of CNC mills and lathes. One of these days I'll actually understand it. Trigonometry was MUCH easier.  ------------------

Larry Bell - email: larry@larrybell.org - gigs - Home Page

2003 Fessenden S/D-12 8x8, 2000 Fessenden S-12 8x8, 1969 Emmons S-12 6x6, 1971 Dobro, Standel and Peavey Amps[This message was edited by Larry Bell on 08 March 2003 at 06:50 AM.] |

Jim Smith

Member From: Plano, TX, USA

|

posted 08 March 2003 07:10 AM

profile

posted 08 March 2003 07:10 AM

profile

Hi Larry, I'll definitely pass your comments on to Jerry.  When I cut the grooves for my Dekley I used the same size cutter (a file in my case). We didn't have a lathe at Dekley, so I put the rollers I wanted to deepen on a threaded shaft with nuts on each end, tightened them against the rollers, and chucked the shaft into a drill press. Then I used a small triangle file that matched the grooves as close as possible on the grooves as the drill press turned. Using different size V's is when you'd have to get into trigonometry to figure where the string will touch the sides. Another thing I just thought of. My simple theory of cutting as deep as you want the string to lower only applies if the sides of the string rest inside the V. If it sits on the top of the V, I think you're back to trigonometry again. [This message was edited by Jim Smith on 08 March 2003 at 07:12 AM.]

|

Larry Bell

Member From: Englewood, Florida

|

posted 08 March 2003 07:44 AM

profile

posted 08 March 2003 07:44 AM

profile

Thanks, Jim -- I'll give it a shot.One more thought:

Anyone who plans to try this should be aware that the hole through the roller must be meticulously deburred so that the fit is snug, but the rollers turn easily. I used the axle itself to slightly ream out the holes and remove imperfections then very lightly dressed both the edges of the rollers themselves and the axle with crocus cloth. If the hole is too large or there are burrs on either the axle or inside of the roller hole, it can cause hysteresis -- that is, the string will not glide smoothly over the roller and it will hang up causing string return problems. Also, be sure to lubricate where the rollers meet the axle and don't get any oil on the string or in the groove. Hope this helps SOMEBODY. I'm about ready to start the process all over again for a new guitar.  One FINAL final thought:

If there is a market for this stuff and we can figger out how to specify the dimensions, my machinist buddy might be game to produce some. He'd need some guarantee of enough business to make it worth his while but might be open to the possibility. The problem is that there's a lot of variation in the dimensions and getting it just right is difficult. I KNOW. I usually stop when it becomes tolerable but don't go much further. On the U-12's it's usually the 6th-8th strings that present the biggest problem. What's a set of gauged rollers worth to you? ------------------

Larry Bell - email: larry@larrybell.org - gigs - Home Page

2003 Fessenden S/D-12 8x8, 2000 Fessenden S-12 8x8, 1969 Emmons S-12 6x6, 1971 Dobro, Standel and Peavey Amps |

Hans Holzherr

Member From: Ostermundigen, Switzerland

|

posted 08 March 2003 08:18 AM

profile

posted 08 March 2003 08:18 AM

profile

The formula is:

r = (2h – d * (1 + 1/cos(90-a/2)))/2

in which

r = inner radius of the V = distance between point of V to center of the roller nut axle

h = string height from the top of the strings to the center of the roller nut axle

d = diameter of string

a = full angle of the V

In case you're not familiar with algebra, start out with the innermost bracket and move outward: divide angle by 2 - subtract result from 90 - take cosine - take reciprocal of that - add 1 - multiply by d - subtract from doubled h - divide by 2. |

Gino Iorfida

Member From: Oakdale, Pennsylvania, USA

|

posted 08 March 2003 09:38 AM

profile

posted 08 March 2003 09:38 AM

profile

So did Emmons ALWAYS have graduated rollers? if not, would the new graduated rollers that the Legrandes use be able to 'drop in' directly to a late model p/p? I would ASSUME so, since they were making the legrandes and the p/p simultaneously at one point, and common sense /economics/marketing 101 would tell me that it woudl be cost effective to make the nut(?) that held the rollers the same, and not change that... but I don't know for sure... |

Larry Bell

Member From: Englewood, Florida

|

posted 08 March 2003 09:46 AM

profile

posted 08 March 2003 09:46 AM

profile

Gino,

I'm not sure that Emmons does have truly gauged rollers. If it's like it was on my p/p (I ASSUME they were the original rollers) there are only two variations -- one with a small groove for unwound and a larger one for wound. That helps some, but with the wide range of gauges on a U-12 and the wider span, it still needed some tweaking to satisfy me.------------------

Larry Bell - email: larry@larrybell.org - gigs - Home Page

2003 Fessenden S/D-12 8x8, 2000 Fessenden S-12 8x8, 1969 Emmons S-12 6x6, 1971 Dobro, Standel and Peavey Amps |

Pete Burak

Member From: Portland, OR USA

|

posted 08 March 2003 09:58 AM

profile

posted 08 March 2003 09:58 AM

profile

I can't find a good picture to post right now, but if you get a chance to look at a Sierra, you'll see that the top of the nut is flush, so that you could slide the bar down the neck and right over and off the nut without hitting the rollers.

The rollers are more like half circles than V's.

For example, on their 14 string guitars, The string guages of the botton 4 are 46, 56, 68, 80, so you can see why they had to go to guaged rollers as the norm.

I don't know if they'd work for other brands, as Sierra uses a pretty hefty diameter roller shaft, but if you have any specific questions, I'd reccomend calling Tom Baker at Sierra. http://www.sierrasteelguitar.com

[This message was edited by Pete Burak on 08 March 2003 at 09:59 AM.] |

Pete Burak

Member From: Portland, OR USA

|

posted 08 March 2003 10:47 AM

profile

posted 08 March 2003 10:47 AM

profile

FWIW, I just took a close look at my axe, and looking straight down the nut from the front of the guitar, no string top breaks the plane of the top of the nut (they are sitting in their respective grooves), but you can see where the bottom of the wound strings hang lower than the plain strings on the area of string between the nut and fret one.

I'm thinking though, even if all your rollers were the same, wouldn't some creative guage selection greatly reduce the problem? |

C Dixon

Member From: Duluth, GA USA

|

posted 08 March 2003 11:47 AM

profile

posted 08 March 2003 11:47 AM

profile

Actual case history. I sent off to Emmons after receiving my new LeGrande in the late 80's. I asked for a set of gauged rollers. The ones they sent me were worse than the ones on the guitar. I had not changed the gauge from the ones that were on the guitar from the factory. The exact same thing happened on both my Sierra Session D-10 and my Excel! Strings not perfectly flat at the nut is my number one pet peave on a steel guitar; and has aggravated me for over 50 yrs. In my book there simply is NO excuse for it. Now having said that, I feel that the ONLY real cure is to have fully adjustable (up and down) nut rollers. This would solve it once and for all. And I feel a very simple way to do this is to mill out a 5/16" inch channel in the keyhead stock design; where the nut rollers presently reside. Then make individual 5/16" square pieces of stock. At the top of this piece would be a milled out area just big enough for a nut axle shaft and roller. A set screw hold is then threaded and installed going down from the top of this piece under the axle at an angle. The angle is necessary to permit the allen adjusting wrench to clear the nut roller. This would permit one to adjust the height of the nut roller while the strings were ON the guitar from the top. Finally the front and rear ends of this channel would be closed in (aesthetically) to make the individual nut roller assemblies captive. This would allow two things: 1. A player could adjust any roller up or down. A simple fixed and flat bottomed LED array (with battery) could test to insure 100% flatness at the tops of all the strings and SEE which one(s) where the offenders. 2. A player could tailor it to fit ANY changes in gauge in a second. I have this drawn up but it always met with a raised eyebrow when I approached a builder. So I shelved it. But I still believe it is a good idea. Finally this; there are some things that are not common knowledge about nut rollers that need to be taken into consideration. And since it involves tone, I feel it is quite important. 1. A nut roller groove that allows the bottom of ths string to touch the groove will not give as brilliant and/or resonant a tone as a groove that only touches the string at two points. One on each side of a V groove for instance. Ron Lashley and I talked about this at length on several ocassions. He was the first person to tell me the "why's and how's" about nut rollers. 2. the sides of a nut roller should NEVER be as high as the tops of the strings. In other words, one should be able to slide the bar clean off and to the left of the nut assembly and still rest on the strings; and slide back over them without touching anything but the strings. Check this out when you are looking at guitars and see just how many times the above is NOT the case. carl |

chas smith

Member From: Encino, CA, USA

|

posted 08 March 2003 11:50 AM

profile

posted 08 March 2003 11:50 AM

profile

Hans, thank you. Normally I just write numbers on the wall and then throw the "accu-dart" at them. |

Doug Earnest

Member From: Branson, MO USA

|

posted 08 March 2003 03:19 PM

profile

posted 08 March 2003 03:19 PM

profile

Thank you Hans. Jim Smith, I tried the approach of using a straight edge and feeler guages to determine the depth the rollers should be cut when I was fine adjusting my 2000 model Zum at Bruce's one day. It does work but what a pain in the tush. Of course we didn't have a cutting tool of the proper size to match the V of the pre-made rollers either so when you made a cut you changed everything, but after about four tries I finally got it. Now it plays like it should and I think it also improves the tone. I dread the thought of going through the process again on my keyless Zum, but it has to be done. I got additional rollers from Sierra when I was still playing that guitar, but they weren't right either. Don Christenson was very kind about helping me, but I didn't mess with the rollers any more. Possibly with the recommended Sierra guages these are the right combination, although my guages don't vary too much. As far as adjustable roller bridges like Fender uses on some of their high end guitars (I think they are Wilkerson brand) and Micro-Frets used to use, that would solve the problem but I can't help but think tone would suffer. You would have to lose contact in the keyhead somewhere, wouldn't you ? I have played with this idea but have never made one. IF SOMEONE WILL MAKE ME SOME STINKIN ROLLERS THAT FIT RIGHT I WON'T HAVE TO !!!!!!!! I'll give $30 for a perfect set for a U12.......but they gotta be perfect.

------------------

Doug Earnest

The only Zum Keyless U12, Fender Cyber Twin |

Larry Bell

Member From: Englewood, Florida

|

posted 08 March 2003 03:54 PM

profile

posted 08 March 2003 03:54 PM

profile

Doug,

That would be about 15 minutes of a master machinist's time. He might be able to make two or three for $30, but I would think $10 apiece would be about what it would cost. That's why I asked what it's worth. If I went to Craig or Dave, the machinists, and told them that I had ten jobs for them at $30 apiece and each would take an hour or more (it's done on a lathe, and would have to be done by hand -- in our shop anyway) THEY WOULD LAUGH ME OUT THE DOOR. Maybe we're beginning to see why they aren't readily available. They are different from brand to brand -- axle size, roller diameter, etc -- and depend on the string gauges -- so getting them perfect the first time is really difficult. It's a custom job unless you are making them only for a given guitar and string set. Speaking of which, I see that Emmons Co. offers a set of 10 (either neck) for $30 -- and calls them 'gauged'. Can anyone with a LeGrande tell us whether they are 10 different slot sizes or just two (one for plain, one for wound)? I'm sure they just sell them 'as is' with no guarantee of anything other than it will fit your Emmons guitar.------------------

Larry Bell - email: larry@larrybell.org - gigs - Home Page

2003 Fessenden S/D-12 8x8, 2000 Fessenden S-12 8x8, 1969 Emmons S-12 6x6, 1971 Dobro, Standel and Peavey Amps |

Larry Bell

Member From: Englewood, Florida

|

posted 08 March 2003 04:07 PM

profile

posted 08 March 2003 04:07 PM

profile

HOLD ON A MINUTE

I just had an idea

Why can't they just be different diameters?Jim? What do you think?

Could you just cut a standard groove -- maybe like the ones that have a small groove for unwound and a larger one for wound -- and make the largest string a given diameter and the smaller strings slightly larger, proportional to the string gauges? If I recall correctly when they made mine they started with square stock and machined them round on the lathe, so varying the diameter would be pretty easy. What say ye???? ------------------

Larry Bell - email: larry@larrybell.org - gigs - Home Page

2003 Fessenden S/D-12 8x8, 2000 Fessenden S-12 8x8, 1969 Emmons S-12 6x6, 1971 Dobro, Standel and Peavey Amps[This message was edited by Larry Bell on 08 March 2003 at 04:08 PM.] |

Doug Earnest

Member From: Branson, MO USA

|

posted 08 March 2003 08:21 PM

profile

posted 08 March 2003 08:21 PM

profile

Larry,

That's why I thought this would be a good project for someone with a "hobby shop" as opposed to a full blown machine shop. If you knew exactly how to make each cut, it really wouldn't take all that long to make a few sets. I'd be glad to make $30 an hour to piddle around making rollers if I had the right equipment (which I don't). |

richard burton

Member From: Britain

|

posted 08 March 2003 11:55 PM

profile

posted 08 March 2003 11:55 PM

profile

Time for a bit of lateral thinking:

Put the roller in the lathe.

Turn a small groove.

Place a piece of guitar string of the desired gauge in the groove.

Take a measurement of the roller (with the guitar string in situ) with a micrometer.

Work out what the measurements are for all 10 or 12 rollers with their respective strings to get the string height consistent.

No trigonometry needed, just a micrometer. |

David L. Donald

Member From: Koh Samui Island, Thailand

|

posted 09 March 2003 05:25 AM

profile

posted 09 March 2003 05:25 AM

profile

To all, a very informative thread. To C Dixon you answered several of my questions in one post, particularly about V groove vs round rollers.

What it the prevalence of rounded rollers, and when was this change to V grooves brought on? Also the adjustable height roller idea has strong merits. (as well as an increased price tag.) But this very well might help intonation issues in general and playing at 1s fret. |

David Reeves

Member From: Florida

|

posted 09 March 2003 05:54 AM

profile

posted 09 March 2003 05:54 AM

profile

Mr. Donald, Mr. Dixon,Respectfully, I am still wondering how the round bottom groove vs. V bottom groove would affect sustain... When you have that steel down there touching them strings, and the fangers of that left hand resting on them strings down in there behind that steel, I am not understanding how that would affect sustain. All of the information provided here has been very interesting. ------------------

"Stump" Reeves

[This message was edited by David Reeves on 09 March 2003 at 06:11 AM.] |

Larry Bell

Member From: Englewood, Florida

|

posted 09 March 2003 06:25 AM

profile

posted 09 March 2003 06:25 AM

profile

Sir Richard,

You come through once again, my friend

That's the most elegantly simple solution yet proposed. I'm gonna try it!  ------------------

Larry Bell - email: larry@larrybell.org - gigs - Home Page

2003 Fessenden S/D-12 8x8, 2000 Fessenden S-12 8x8, 1969 Emmons S-12 6x6, 1971 Dobro, Standel and Peavey Amps |

richard burton

Member From: Britain

|

posted 09 March 2003 06:46 AM

profile

posted 09 March 2003 06:46 AM

profile

Thank you, Larry.

I've always thought that I deserve a knighthood! |

C Dixon

Member From: Duluth, GA USA

|

posted 09 March 2003 07:08 AM

profile

posted 09 March 2003 07:08 AM

profile

David,I did not say sustain. I said, "A nut roller groove that allows the bottom of ths string to touch the groove will not give as brilliant and/or resonant a tone as a groove that only touches the string at two points." What I should have said is, "A roller nut that allows the bottom AND sides of the string........" Sorry bout that. This is what Sierra does. And IMO has been poor design from day one. This is not a new theory and predates PSG by dozens of years. Eddie Alkire new this eons ago. That is why on most of his guitars, the nut is a piece of aluminum that comes almost to a point at the top. Alkire guitars have incredible sound in most cases. And I attribute the shape of the nut and bridge for a major part of this. The ideal situation is for the string to touch the nut (be it fixed or roller) at ONLY one point. This is generally impractical. And the ideal "point" causes a "screeching zzzzip" when tuning the wound strings. The flatter the nut, the more loss of tone and resonance you get. The sharper the nut, you get the reverse. When you use a roller, there is a poblem IF the roller has a groove in it. And most do. The two most prevalent choices are round bottom or V groove. Most use V groove I believe. This means two points of the string touch the V. Which is NOT as good as if only one point touched the string. But is the next best thing. Round bottom, where the string touches the sides AND the bottom are unacceptable, IMO. Actually there is no real reason for the roller to be grooved at all; IF the pull is in a straight line parallel to the length of the guitar. There is no groove in most changers. So why have one at all in the nut. If this were the case, we are back to the "one point" scenario. Which would be better. (This provided the string does NOT tend to wrap around the roller such as strings 1 and 10 on an Emmons PSG). By the way, this is the major cause of players complaining that the 1st and 10th strings do not have that zing like the other strings do on an Emmons. Also on a side note. Experience has proven that there is much more to making gauged rollers "absolutely flat" than what has been described in this thread. "The proof of the pudding is in the eating". And NO body to date (that I know of) makes gauged roller nuts that result in the strings being 100% flat across the tops of all strings. The one person I thought that could and would do it, turned out to be a rip-off, sadly. It appears very simple. But try it on a lathe. The results do not bear this out. The reason for this is, trig IS necessary and SO is a bit of calculus. The angle of the groove versus the cross section of the string gauge, plus the the radii of the roller cause a mathematical variable that is NOT easy to solve, WHEN you are talking about 10 or 12 different gauges. If it was easy, I am certain the manufactuters would have long since made it work. The facts of the matter is this has NOT been the case. If you doubt this, simply call a builder, tell them what gauges you have and ask them to make you a set of gauged roller nuts. THEN, when you get them, see for yourself. Remember, unless the top of ALL strings are dead level (at the nut), you ARE going to get string rattle with light bar pressure at the first fret. That bubba is the "eating"  I am sorry to say the results have been painfully sad. Thus the reason for this thread, and my (and others) 100% futility in trying to get a set that were completely satisfactory. carl |

David Reeves

Member From: Florida

|

posted 09 March 2003 07:14 AM

profile

posted 09 March 2003 07:14 AM

profile

Mr. Dixon,

God Bless Your Heart,I went back and re-read your post... y'know, my wife always tells me that I don't listen... I guess that I don't read right neither.... ------------------

"Stump" Reeves

|

Doug Earnest

Member From: Branson, MO USA

|

posted 09 March 2003 09:28 AM

profile

posted 09 March 2003 09:28 AM

profile

Richard Burton,I agree with the process you outlined for making a set of rollers "from scratch". That's basically what I did when I reworked the set on the Zum 2000. If memory serves me I only had to modify strings 7 thru 12. With the proper cutter it wouldn't be any big deal, really. And the right tool isn't hard to obtain, we just don't happen to have one, guess we should buy one, huh?? That will fix my problems, the rest of you guys are on your own !!! (ha ha) I suppose the manufacturers don't fix this because it would involve having maybe 7 different rollers as opposed to 3, and on 10 strings it isn't as much of an issue. But I have yet to sit down at a 12 that didn't have this problem initially. It probably doesn't bother a lot of people, but it sure irritates me. I don't like to apply a lot of bar pressure. Of course we re-worked Jeff Newman's guitar last year and it wasn't perfect either, but doesn't seem to hurt his playing. Personally, I need all the help I can get. Thanks to all for the good ideas and participation in this thread.

------------------

Doug Earnest

The only Zum Keyless U12, Fender Cyber Twin |

Doug Earnest

Member From: Branson, MO USA

|

posted 09 March 2003 09:38 AM

profile

posted 09 March 2003 09:38 AM

profile

Mr.Dixon,

The keyless Zum pulls the strings thru the tuner in a straight line. I think I'll make a set of rollers for it that don't have any grooves, and vary the diameter to fix the string height. This would be a good test of the single point vs. V notch theory in terms of tone, don't you think? I'm pretty sure that on the other Zum the bass strings are sitting on the bottom of the string notch (not necessarily a V) and at about the time I made the switch it developed this GREAT BIG throaty growl. It sounded good previously, but is exceptional now. Even Bruce says so and he's darn picky (that's good). I'm pretty sure there's a correlation in there.------------------

Doug Earnest

The only Zum Keyless U12, Fender Cyber Twin |

Earnest Bovine

Member From: Los Angeles CA USA

|

posted 09 March 2003 10:17 AM

profile

posted 09 March 2003 10:17 AM

profile

FWIW Bruce Zumsteg makes only two different groove depths on his nut rollers. I was surprised to learn that on 10 string E9, the two deep ones are used not on strings 9 and 10, but on strings 1 and 2. The difference in depth is much greater than the difference in string diameters for these high E9 strings (not so for low strings on C6 or extended E9). Apparently this helps the tone of the high G# string. It works well.

Thus trial and error may work better (sound better) than a theoretical calculation that puts all the string tops at the same height.

And the calculation is well within the capability of Jethro Bodine if the string sits in a groove whose V shape has a right angle at the bottom.

|

Larry Bell

Member From: Englewood, Florida

|

posted 09 March 2003 10:27 AM

profile

posted 09 March 2003 10:27 AM

profile

I just keep coming up with ideas that spawn a half dozen more questions.  But, the tops of the strings don't HAVE to be the same height to be PLANE. There's no problem with the big ones being higher than the little ones as long as the top of the strings are in a straight line. That line can go downhill and still achieve our 'no rattle' / less bar pressure requirement. ------------------

Larry Bell - email: larry@larrybell.org - gigs - Home Page

2003 Fessenden S/D-12 8x8, 2000 Fessenden S-12 8x8, 1969 Emmons S-12 6x6, 1971 Dobro, Standel and Peavey Amps[This message was edited by Larry Bell on 09 March 2003 at 10:41 AM.]

|

Earnest Bovine

Member From: Los Angeles CA USA

|

posted 09 March 2003 10:37 AM

profile

posted 09 March 2003 10:37 AM

profile

quote:

But, the tops of the strings don't HAVE to be the same height to be PLANE. There's no problem with the big ones being higher than the little ones as long as the top of the strings are in a straight line

Right, but that would be the case only if the string diameters changed in a linear fashion, but they don't. The lowest string is fatter than that, etc.

The Zum system works well on the high strings, but works poorly on the low strings. On my 12 string E9, puts the deep grooves on strings 1,2,11,12. I still get rattle on most of the wound strings except 12.

|

Larry Bell

Member From: Englewood, Florida

|

posted 09 March 2003 10:46 AM

profile

posted 09 March 2003 10:46 AM

profile

You may have missed my point, Doug

Maybe all I did was state the obvious but I'm pretty good at that.  I suggested that the grooves could either be cut such that the height of the top of each string is the same OR such that they graduated SMOOTHLY (you cut the grooves so the height decreases evenly down to the smaller ones). I still think it's easier just to put the string in the groove and adjust the grooves for all rollers to make the same distance from the bottom of the roller to the top of the string. That's clearly do-able AND I believe it can be done by either varying the groove depth or the roller diameter. ------------------

Larry Bell - email: larry@larrybell.org - gigs - Home Page

2003 Fessenden S/D-12 8x8, 2000 Fessenden S-12 8x8, 1969 Emmons S-12 6x6, 1971 Dobro, Standel and Peavey Amps[This message was edited by Larry Bell on 09 March 2003 at 10:49 AM.] |

C Dixon

Member From: Duluth, GA USA

|

posted 09 March 2003 10:52 AM

profile

posted 09 March 2003 10:52 AM

profile

Larry is correct. If I implied that the tops of the strings had to be parallel with the neck I apologize. As long as the tops are in a straight line as Larry pointed out is fine. And yes, it would be much easier to calculate the size of the nut roller IF the string did not fit into a groove. In fact it would be better in every way as far as I am concerned. There MIGHT be a slight problem on "keyless" guitars in that the string may tend to shift away from the center of the roller according to the wrap around the locking screw. Not sure. But all in all, I think it would still be better than a groove, carl | |

The Steel Guitar Forum

The Steel Guitar Forum

Pedal Steel

Pedal Steel

Graduated nut rollers, swapping between brands? (Page 1)

Graduated nut rollers, swapping between brands? (Page 1)