|

Author

|

Topic: Fender 400 bridge and nut modified?

|

Russ Tkac

Member From: Waterford, Michigan, USA

|

posted 06 December 2005 01:16 PM

profile

posted 06 December 2005 01:16 PM

profile

I saw this on eBay and it looks like the nut and bridge have been modified with rollers. Does anyone know if this is a Fender mod or not?

|

Jay Yuskaitis

Member From: Massachusetts, USA

|

posted 06 December 2005 01:23 PM

profile

posted 06 December 2005 01:23 PM

profile

Original long scale Fender------------------

|

Jody Carver

Member From: The Knight Of Fender Tweed~ Dodger Blue Forever

|

posted 06 December 2005 03:09 PM

profile

posted 06 December 2005 03:09 PM

profile

Those anchors or extensions you see at the bridge are factory. the purpose was to shorten the length of the string to prevent breaking.That is one fine 400 guitar. More than likley a 57 model. |

Jim Sliff

Member From: Hermosa Beach California, USA

|

posted 06 December 2005 04:59 PM

profile

posted 06 December 2005 04:59 PM

profile

That's the same nut and bridge as Sneaky's. My '57 1000 Does NOT have the roller nut or bridge, BTW.[This message was edited by Jim Sliff on 06 December 2005 at 09:09 PM.] |

Russ Tkac

Member From: Waterford, Michigan, USA

|

posted 06 December 2005 06:40 PM

profile

posted 06 December 2005 06:40 PM

profile

Thanks for the info. |

Jody Carver

Member From: The Knight Of Fender Tweed~ Dodger Blue Forever

|

posted 06 December 2005 08:16 PM

profile

posted 06 December 2005 08:16 PM

profile

Jim those roller bridges were an in field modification done by saleman and Fender Service Centers. Shortly after the factory then made them stock from production. It is obvious if you have no bridge assembly as that shown in the photo, it was not modified in the field or at an "Authorized Fender Service Center" This information can be obtained in Richard Smith's book "Fender The Sound Heard Round The World". |

Jim Sliff

Member From: Hermosa Beach California, USA

|

posted 06 December 2005 09:08 PM

profile

posted 06 December 2005 09:08 PM

profile

Most of the early-types (flat pickup) that I've seen don't have the "in field" modification. It'd be interesting to look at one closely and compare it to the roller nuts on later guitars to see what COULD be used as roller nuts/brideges on the ones with straight bars.Although my bar-type 1000, which I lube with dry Teflon lubricant, hasn't broken a string yet. Followup - I just compared the pictures to my 1000, and 1) the bridge uses completely different positions for mounting holes. The stock ones use two vertical screw-through plates at the hog rings while the "upgrade uses 4 screws into the body; 2) the stock nut is mounted with two screws through the top - the mounting on the "upgade" isn't apparent. The "field modification" had to be pretty complicated with a bunch of drilling involved.[This message was edited by Jim Sliff on 06 December 2005 at 09:14 PM.] |

Russ Tkac

Member From: Waterford, Michigan, USA

|

posted 07 December 2005 01:46 AM

profile

posted 07 December 2005 01:46 AM

profile

This one looks like a mod. Is it possible to find these parts and upgrade a fixed bridge?  |

Jim Sliff

Member From: Hermosa Beach California, USA

|

posted 07 December 2005 05:57 AM

profile

posted 07 December 2005 05:57 AM

profile

It would be even better if someone made one to use the four existing scews rather than drilling four new holes. |

Dave Zirbel

Member From: Sebastopol, CA USA

|

posted 07 December 2005 07:34 AM

profile

posted 07 December 2005 07:34 AM

profile

I wouldn't mind having rollers on mine. Maybe we can all chip in and have some made.  Tommy Spurlock in Texas said he had some made for his guitars. I'll call him and see if he has any extra. When I talked to hin a few months ago he said he was having a bunch of parts made. He plans on carrying on the Sneaky Pete legacy and is converting old cable guitar to rods. |

Russ Tkac

Member From: Waterford, Michigan, USA

|

posted 07 December 2005 08:45 AM

profile

posted 07 December 2005 08:45 AM

profile

Dave,Let me know what you find out. I'd like a set on rollers for an old 400. Thanks,

Russ |

Dave Zirbel

Member From: Sebastopol, CA USA

|

posted 07 December 2005 08:56 AM

profile

posted 07 December 2005 08:56 AM

profile

I was also thinking about talking to Gene Parsons who invented the B-Bender. He is a master machinest and has a shop 2 hours away. He also plays old Fender PSGs and he would understand what we're after. He charges $50 an hour just to draw the plans for the parts so I may try to generate some interest and sell some parts just to hopefully break even. I have some ZB parts in mind for him too.Hopefully I'll move ahead on this after the Holidays. Dave I'll let you know.[This message was edited by Dave Zirbel on 07 December 2005 at 09:00 AM.] |

Gary Spaeth

Member From: Wisconsin, USA

|

posted 09 December 2005 08:56 PM

profile

posted 09 December 2005 08:56 PM

profile

i'd like to give making a roller bridge a shot. i have the tools to do it. send me some dimensions or a bridge if you can spare one. |

Jim Sliff

Member From: Hermosa Beach California, USA

|

posted 09 December 2005 10:44 PM

profile

posted 09 December 2005 10:44 PM

profile

Gary - how about I send you the bridge and nut off my C6 1000 neck to measure for dimensions and mounting? I could include pics of the existing mounting as well. |

Jim Sliff

Member From: Hermosa Beach California, USA

|

posted 10 December 2005 07:09 AM

profile

posted 10 December 2005 07:09 AM

profile

OK, I've talked to Gary and the parts go out today if possible. This should be cool!! |

Gary Spaeth

Member From: Wisconsin, USA

|

posted 10 January 2006 09:27 AM

profile

posted 10 January 2006 09:27 AM

profile

i sent jim's bridge back with a modification that might work. jim is testing it out now. cross your fingers. |

Keith Cordell

Member From: Atlanta

|

posted 10 January 2006 09:36 AM

profile

posted 10 January 2006 09:36 AM

profile

This really sounds promising! |

Patrick Ickes

Member From: Upper Lake, CA USA

|

posted 10 January 2006 09:24 PM

profile

posted 10 January 2006 09:24 PM

profile

I too am interested in this. I wonder if the great tone we all love from these guitars will be lost in switching to a roller nut. I'm looking forward to the results.

Patrick |

Gary Spaeth

Member From: Wisconsin, USA

|

posted 16 January 2006 09:23 AM

profile

posted 16 January 2006 09:23 AM

profile

how's it working jim. better answer by email if it's a big flop. haha! |

Jim Sliff

Member From: Hermosa Beach California, USA

|

posted 16 January 2006 10:02 AM

profile

posted 16 January 2006 10:02 AM

profile

Actually it seems to be working pretty well! I've just been busy and forgot to answer. The only downside is string changing - the moving parts tend to use gravity and go upside-down. When playing they work fine, though, with no discernable difference in tone. |

Gary Spaeth

Member From: Wisconsin, USA

|

posted 19 January 2006 04:44 AM

profile

posted 19 January 2006 04:44 AM

profile

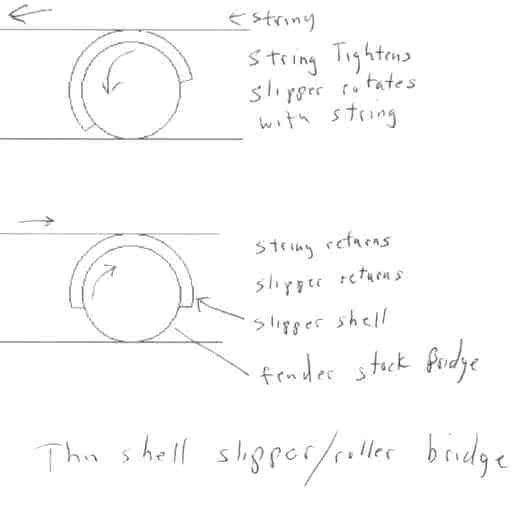

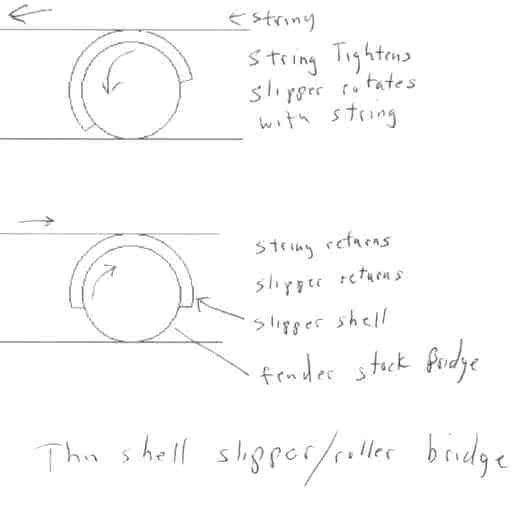

jim. i made those "slipper shells" so they would snap off the bridge by pulling up on them. as you put one string on you could snap the shell on first or leave the new string loose enough to pull it up and snap the shell on under it. |

Gary Spaeth

Member From: Wisconsin, USA

|

posted 29 June 2006 09:42 PM

profile

posted 29 June 2006 09:42 PM

profile

here's the idea behind what i did for jim.  |

Jim Sliff

Member From: Hermosa Beach California, USA

|

posted 29 June 2006 11:06 PM

profile

posted 29 June 2006 11:06 PM

profile

this pic is posted on a couple of other threads. hot subject right now. Here's what Gary made - when I changed strings I didn't even them out...that's why the gaps...but it makes no difference. They work great. this neck is tuned to the top-8 of E9, and I have yet to break a 3rd...or any...string, and it's ben used a lot. Proof's in the pudding, and this is a great idea that works! |

Tim Jones

Member From: Andover, KS, USA

|

posted 30 June 2006 09:48 PM

profile

posted 30 June 2006 09:48 PM

profile

My 1000 didn't have any of those little 'hognose' clips when I got it but it did have the roller bridge.After a few string breakages, I took some clips off an old 400 I have.... Result is LESS string breakage, and it's probably not completely avoidable in these old machines. Tim Jones

~)Fender 1000 and nothin' else(~ |

Jim Sliff

Member From: Hermosa Beach California, USA

|

posted 01 July 2006 07:31 AM

profile

posted 01 July 2006 07:31 AM

profile

The hognose rings probably make more difference in string breakage than the bridge. With the rings the string ball end is at about a 45 degree angle - without and attached directly to the changer, it's nearly 90 degrees, and a weak spot in the system. |

Patrick Ickes

Member From: Upper Lake, CA USA

|

posted 01 July 2006 09:24 AM

profile

posted 01 July 2006 09:24 AM

profile

I've never had a string break at the hog ring. I doubt that would influence string breakage as the string is only bent once when brought up to pitch. That's a great, simple idea Gary came up with! I use LPS 1 greaseless lubricant on my nut and bridge. I put on a set of strings shortly before the San Jose Jam 1 1/2 years ago and I haven't broken a string since. I don't advocate old strings, but I'd like to dispute the common belief that E9 w/G# can't be used on old Fender Cable Guitars.  The lubricant works very much the same as Gary's slippers by providing a surface "barrier" between the guitar and the strings. Just as Piston rings need oil to prevent scoring cylinder walls, keep just enough lubricant applied to do the job. The lubricant works very much the same as Gary's slippers by providing a surface "barrier" between the guitar and the strings. Just as Piston rings need oil to prevent scoring cylinder walls, keep just enough lubricant applied to do the job.

I'm off to Healdsburg for trail ride gig. The dust may spell death to my theory.

Patrick

|

Jim Sliff

Member From: Hermosa Beach California, USA

|

posted 01 July 2006 10:07 AM

profile

posted 01 July 2006 10:07 AM

profile

I use Gary's gadget AND Triflow teflon lube...and have never broken one with it tuned to E9 either (with hog rings installed...never had one without).I don't think string breakage is an inherent problem with the long-scale Fenders. Properly set up, lubed and maintained, I think they work just fine. |

The Steel Guitar Forum

The Steel Guitar Forum

Pedal Steel

Pedal Steel

Fender 400 bridge and nut modified?

Fender 400 bridge and nut modified?

The lubricant works very much the same as Gary's slippers by providing a surface "barrier" between the guitar and the strings. Just as Piston rings need oil to prevent scoring cylinder walls, keep just enough lubricant applied to do the job.

The lubricant works very much the same as Gary's slippers by providing a surface "barrier" between the guitar and the strings. Just as Piston rings need oil to prevent scoring cylinder walls, keep just enough lubricant applied to do the job.